what is a rockwell hardness test|rockwell hardness test explained : service The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. WEB19 ° 27 °. 40mm. saiba mais. Obtenha informações atualizadas sobre as condições climáticas na agricultura em Entre-Ijuís - RS nos próximos 15 dias. Conheça o Agroclima.

{plog:ftitle_list}

As said in this article's introduction, your search for the top torrent sites should be based on certain criteria. More precisely, you'll want access to . Ver mais

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject.

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .It’s a measuring system of non-destructive metallurgical testing that determines how hard and strong steel such as that used in knife-making truly is. To accurately express metal hardness, engineers use a standard process .

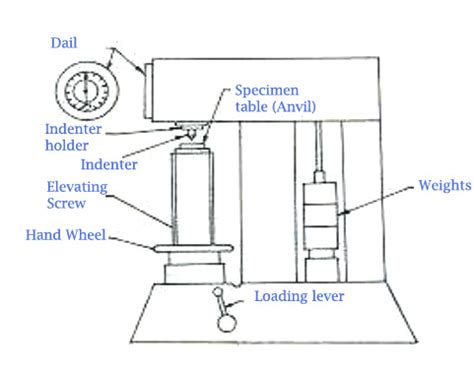

Rockwell hardness testing equipment is quite straightforward. It involves a mechanical operation where an indenting tool gets pressed against the metal subject surface at different rates while the indentation depth gets recorded. .Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.

The testing of a blade with a file only happens after the quench where the blade is at maximum hardness. It is just a test to see if any hardening occurred, not to test the final hardness of the blade. After tempering, a file will cut a blade relatively easily. Matthew Parkinson makes hardness testing chisels in the lower rockwell levels for .Rockwell Hardness Test: In Brinell Hardness Test the indenter is a spherical Tungsten Carbide Ball: For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness greater than 650 HB can not be measured with the Brinell Scale setup.

The Rockwell hardness test is widely used to measure the hardness of materials, including metals, plastics, and ceramics. To apply the formula for Rockwell hardness, you will need to have the following information: The load applied .

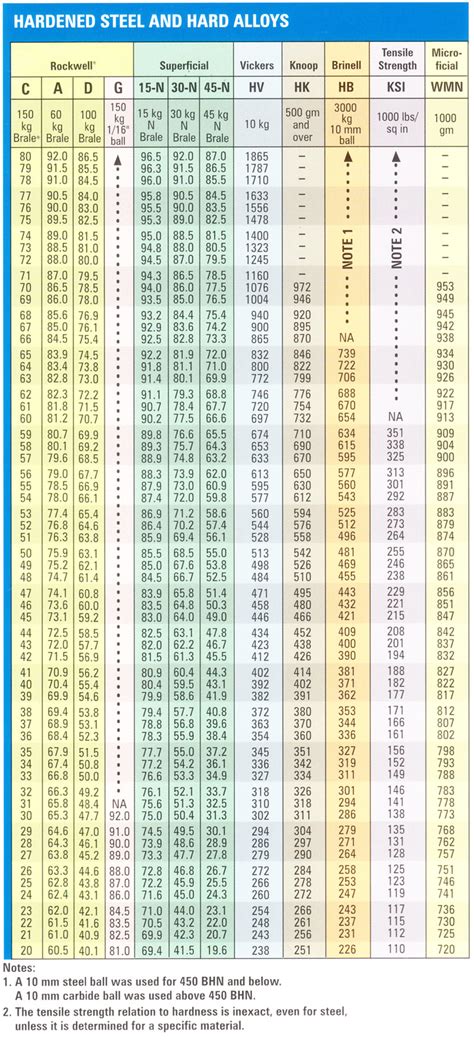

The hardness of aluminum can be assessed through various testing methods, including Brinell hardness and Rockwell hardness. The hardness of aluminum alloys is related to the other metals they are alloyed with, such as magnesium, manganese, and copper. The addition of these elements can significantly enhance the corrosion resistance and hardness .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .Rockwell Hardness Test; Rockwell hardness test method utilizes a Rockwell hardness testing machine equipped with either a tungsten carbide ball indenter or a diamond indenter. For the ball indenter, four different sizes exist, while the diamond indenter only exists as a single type. However, the loads required to carry out this test ranges from .Converting hardness Rockwell B (HRB) to hardness Rockwell C (HRC) is a usual practice for many designers when specifying the hardness value of a material. This conversion is possible using charts and tables calculated using formulas to get approximate but acceptable values that can be interchanged for the different Rockwell hardness testing scales.

The Rockwell hardness test measures the resistance of a material to indentation. The indentation is made with a standardized ball indenter that has a flat circular shape and a radius of 25.4 mm or .01 inches at its largest diameter. The ball indenter is pressed against the surface to be measured at a constant rate of 0.7660 kg per square inch .

cost of tensile strength testing machine

rockwell hardness testing chart

Hardness testing methods stand on the sample objects and their features. Hardness testing methods stand on the sample objects and their features. . The speed of the method is not very efficient relative to Brinell or Rockwell hardness test. Apart from the time which is consumed for the preparation of the test, it takes almost a minute to .In which hardness testing method does an experienced operator test the material by scratching the surface?, 3. Which hardness testing method uses a 15N Scale? and more. . Which Rockwell hardness scale is most commonly used for softer materials? A) 15N B) B C) C D) BHN. B. 9. Which hardness testing method employs either a ball or a diamond .

Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. 9. ROCKWELL SCALE The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are different scales, denoted by a single letter, that use different loads or . what is brinell hardness test, brinell hardness test, brinell hardness test in hindi👉Material science and engineering के Pdf Notes के लिए इस वीडियो को .

If a Rockwell test is conducted on cylindrical parts, then, due to the lower resistance of the test surface with respect to the indenter, the following correction values – depending on the specimen curvature radius and the Rockwell scale used – must .

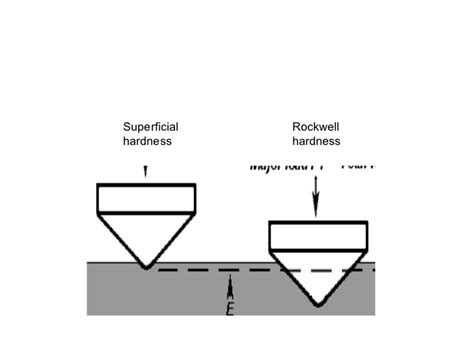

The Macro Rockwell hardness test; The Macro Rockwell hardness test is measured by the depth of the indentation when you apply load on the sample object. The application of such methods is used to analyze the value of . Rockwell Hardness Test is one method of testing the hardness of a material and uses the Rockwell scale based on indentation hardness of a material. History of the Rockwell Hardness Tester Hugh M. Rockwell (1890–1957) and Stanley P. Rockwell (1886–1940) from Connecticut co-invented the Rockwell Hardness Tester in 1919.II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.

Deep Dive into Rockwell Hardness Testing. The Rockwell method is the gold standard for measuring a material’s resistance to indentation. The process involves an initial minor load, followed by a more substantial major load. The subsequent depth of penetration under this major load determines the Rockwell number, representing the material’s .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

For instance, in the Rockwell hardness test, hardness values range from 0 to 100 based on indentation depth, but each test method defines its scale uniquely. Hardness values themselves lack a specific unit and solely represent a value on the scale corresponding to a particular test. However, they are accompanied by a designation indicating the .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation. . The Rockwell hardness of a firearm metal refers to its resistance to penetration or indentation. This measurement helps determine the durability and strength of the metal used in firearms. . Rockwell hardness is measured using specialized testing equipment that applies a specific amount of force to a material and then measures the depth of .

rockwell hardness tester diagram

The Rockwell hardness test is cheaper and can be used on a wider range of materials, while the Vickers hardness test is expensive because of the optical measurement material used to take the measurements and the time required to perform the test. However, it can be used for very thin materials such as aluminum foils and other non-ferrous materials. Rockwell hardness testing involves indenting a material with either a diamond or steel ball indenter under a minor preload and then a major load. The difference in indentation depth is used to determine the Rockwell hardness number on various scales. There are 30 Rockwell scales that use different indenters and loads.The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional examinations in the sequence. Process The Rockwell Hardness test and its counterparts [.]

dartec tensile testing machine

WEBThe Loss Prevention Officer suspects the younger suspect has been stealing items from the store. After a strip search, the stolen goods are found in her mothers bag. It is clear .

what is a rockwell hardness test|rockwell hardness test explained